Factory Price For Chery Steering Gear - Car body protector front bumper guard for chery – Qingzhi

Factory Price For Chery Steering Gear - Car body protector front bumper guard for chery – Qingzhi Detail:

| Product name | Bumper |

| Country of origin | China |

| OE number | A13-2803501-DQ |

| Package | Chery packaging, neutral packaging or your own packaging |

| Warranty | 1 year |

| MOQ | 10 sets |

| Application | Chery car parts |

| Sample order | support |

| port | Any Chinese port,wuhu or shanghai is best |

| Supply Capacity | 30000sets/months |

The plastic plate under the front bumper is called the deflector.

In order to reduce the lift generated by the car at high speed, the car designer not only improved the appearance of the car, but also installed a downward inclined connecting plate under the bumper at the front of the car. The connecting plate is integrated with the front apron of the vehicle body, and a suitable air inlet is opened in the middle to add atmospheric fluidity to reduce the air pressure under the vehicle.

Protection method of bumper

1. Judge the position of bumper with angle indicator post

The mark erected at the corner of the bumper is the indicator post, which can correctly confirm the corner position of the bumper, prevent the damage of the bumper and improve driving skills.

2. Install corner rubber to reduce bumper damage

The corner of the bumper is the most vulnerable part of the car shell, which is easy to be scratched by people with poor driving feeling. Corner rubber can protect this part. It is easy to install. It is directly attached to the corner of the bumper, which can reduce the damage of the bumper.

The plastic plate under the front bumper is called the deflector.

It is the deflector. In order to reduce the lift generated by the car when driving at high speed, the car designer has improved the car shape, tilted the whole body forward and down to generate downward pressure on the front wheel, changed the rear end to short and flat, reduced the negative air pressure acting from the rear of the roof and prevented the rear wheel from floating, A downward inclined connecting plate is also installed under the bumper at the front end of the car.

This plastic plate is fixed with screws or buckles. As long as it doesn’t break, it doesn’t matter if it falls or becomes loose. Just tighten the screws and clamp the buckles tightly.

Process analysis of automobile deflector:

The original process was manual drilling on the metal plate, which was too low efficiency and high cost to produce on a large scale. The blanking and punching scheme can improve the production efficiency and quality and reduce the cost.

Due to the small hole spacing of parts, the sheet metal is easy to bend and deform during punching, and in order to ensure the strength of die working parts and punch qualified parts, the wrong time punching method is adopted; Due to the large number of holes, in order to reduce the blanking force, the process die adopts high and low cutting edges.

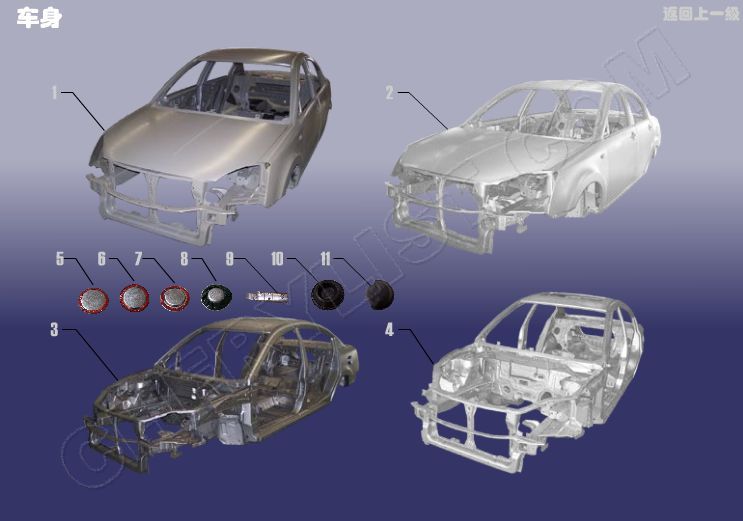

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for Factory Price For Chery Steering Gear - Car body protector front bumper guard for chery – Qingzhi , The product will supply to all over the world, such as: San Diego , Cambodia , Armenia , Profession, Devoting are always fundamental to our mission. We have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!