Low MOQ for Chery Elara Car Parts - ELECTRICAL FLUID TANK PIPELINE for CHERY TIGGO T11 – Qingzhi

Low MOQ for Chery Elara Car Parts - ELECTRICAL FLUID TANK PIPELINE for CHERY TIGGO T11 – Qingzhi Detail:

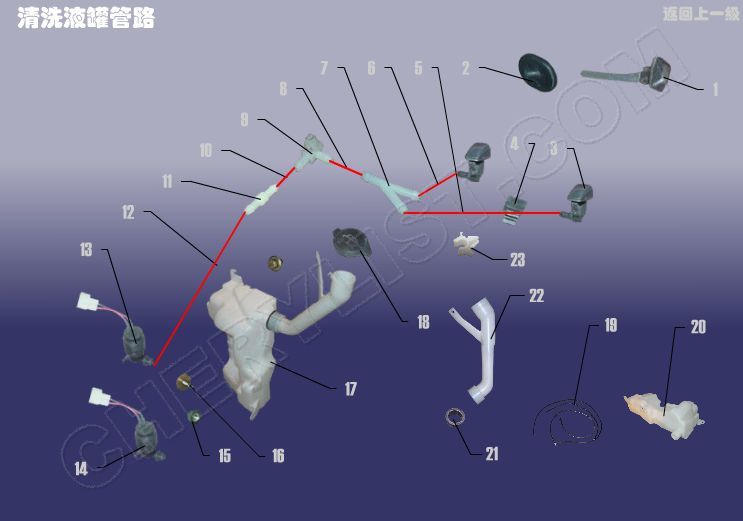

1 T11-5612011 NOZZLE WASHER-FRT

2 T11-5612013 RING RUBBER

3 T11-5207327 NOZZLE WASHER-F.WIND

4 T11-5207331 CLIP BLACK

5 T11-5207319 PIPE2

6 T11-5207317 PIPE1

7 T11-5207313 CONNECTOR

8 T11-5207321 PIPE3

9 T11-5207311 CONNECTOR

10 T11-5207323 PIPE4

11 T11-5207315 CONNECTOR

12 T11-5207325 PIPE5

13 T11-5207125 MOTOR WIPER

14 T11-5207127 MOTOR WIPER

15 Q33006 NUT HEXAGON

16 Q1460620 BOLT HEXAGON HEAD

17 T11-5207110 TANK WASHER-FRONT

18 T11-5207111 CAP TANK

19 T11-5207310 PIPE ASSY – FRONT WASHER WINDSHIELD

20 T11-5207113 TANK – WASHER

21 T11-5207129 RING – RUBBER

22 T11-5207131 GUIDE PIPE

23 T11-5207329 CLIP WHITE

The first connection between the fuel filter and the oil pump is the oil inlet pipe, and the thinner oil pipe returned from the fuel injector is the oil return pipe.

There are three types of oil pumps: In-line type, distribution type and single type. No matter which type, the key of oil pump lies in the word “pump”. The quantity, pressure and time of pump oil shall be very accurate and automatically adjusted according to the load. Oil pump is a component with fine processing and complex manufacturing process. The oil pump of general automotive diesel engine at home and abroad is produced by a few professional factories in the world.

The oil pump can only operate with a power source, and the camshaft at the lower part of it is driven by the engine crankshaft gear. The key part of the fuel injection pump is the plunger. If we compare it with the common syringe in the hospital, the movable plug is called the plunger, and the needle cylinder is called the plunger sleeve. Suppose a spring is installed in the needle cylinder against one end of the plunger, and the other end of the plunger contacts the camshaft. When the camshaft rotates for one week, the plunger will move up and down in the plunger sleeve once, This is the basic movement mode of fuel injection pump plunger.

The plunger and plunger sleeve are very precision parts. There is an inclined groove on the plunger body, and a small hole on the plunger sleeve is called the suction port. This suction port is filled with diesel. When the inclined groove of the plunger faces the suction port, the diesel enters the plunger sleeve. When the plunger is pushed to a certain height by the camshaft, the inclined groove of the plunger is staggered with the suction port, and the suction port is closed, so that the diesel can neither be sucked in nor pressed out. When the plunger continues to rise, it compresses the diesel, When the diesel pressure reaches a certain level, it will open the check valve and rush out into the fuel injection nozzle, and then enter the cylinder combustion chamber from the fuel injection nozzle. Each time the plunger discharges a certain amount of diesel, only part of it is injected into the cylinder, and the rest is discharged from the oil return hole, and the fuel injection quantity is adjusted by increasing or decreasing the discharged oil return quantity.

When the plunger rises to the “upper point” and moves down, the inclined groove of the plunger will meet the suction port again, and the diesel oil will be sucked into the plunger sleeve again. Repeat the above action again. Each group of plunger system of in-line fuel injection pump corresponds to one cylinder, and there are four groups of plunger systems in four cylinders. Therefore, the volume is relatively large and is mostly used in medium-sized and above vehicles. For example, diesel engines on buses and trucks generally use in-line fuel injection pumps.

Product detail pictures:

Related Product Guide:

As a way to provide you advantage and enlarge our organization, we even have inspectors in QC Crew and guarantee you our greatest assistance and product or service for Low MOQ for Chery Elara Car Parts - ELECTRICAL FLUID TANK PIPELINE for CHERY TIGGO T11 – Qingzhi , The product will supply to all over the world, such as: Pakistan , Jeddah , Czech republic , Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.