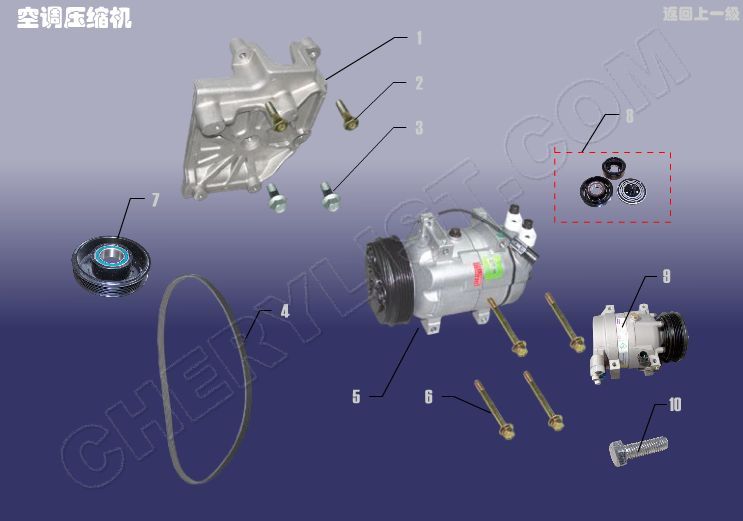

Manufacturer for Chery Qq Bearing - AC SYSTEM COMPRESSOR for CHERY EASTAR B11 – Qingzhi

Manufacturer for Chery Qq Bearing - AC SYSTEM COMPRESSOR for CHERY EASTAR B11 – Qingzhi Detail:

B11-8104021 BRACKET – COMPRESSOR

Q1841040 BOLT – HEXAGON FLANGE

Q184C1025 BOLT

MD317245 V BELT

B11-8104010 BRACKET ASSY – COMPRESSOR

Q14608100 BOLT

B11-8104017 PULLEY-COMPRESSOR

B11-8104310AB MAGNET CLUTCH

B11-8104010AB BRACKET ASSY – COMPRESSOR

B11-8105015 BOLT

11 T11-3708110 STARTER

1. Compression process: the compressor sucks the low-temperature and low-pressure refrigerant gas at the outlet of the evaporator, compresses it into high-temperature and high-pressure gas, and discharges it from the compressor.

4. Endothermic process: the mist refrigerant liquid enters the evaporator. At this time, the boiling point of the refrigerant is far lower than the temperature in the evaporator, so the refrigerant liquid evaporates into gas. In the evaporation process, a large amount of surrounding heat is absorbed, and then the ‘refrigerant vapor with low temperature and low pressure’ enters the compressor again. The above process is carried out repeatedly to reduce the air temperature around the evaporator.

1. Compression process: the compressor sucks the low-temperature and low-pressure refrigerant gas at the outlet of the evaporator, compresses it into high-temperature and high-pressure gas, and discharges it from the compressor.

4. Endothermic process: the mist refrigerant liquid enters the evaporator. At this time, the boiling point of the refrigerant is far lower than the temperature in the evaporator, so the refrigerant liquid evaporates into gas. In the evaporation process, a large amount of surrounding heat is absorbed, and then the refrigerant vapor with low temperature and low pressure enters the compressor again. The above process is carried out repeatedly to reduce the air temperature around the evaporator.

1. Compression process: the compressor sucks the low-temperature and low-pressure refrigerant gas at the outlet of the evaporator, compresses it into high-temperature and high-pressure gas, and discharges it from the compressor.

4. Endothermic process: the mist refrigerant liquid enters the evaporator. At this time, the boiling point of the refrigerant is far lower than the temperature in the evaporator, so the refrigerant liquid evaporates into gas. In the evaporation process, a large amount of surrounding heat is absorbed, and then the refrigerant vapor with low temperature and low pressure enters the compressor again. The above process is carried out repeatedly to reduce the air temperature around the evaporator.

Product detail pictures:

Related Product Guide:

Now we have highly developed devices. Our items are exported towards the USA, the UK and so on, enjoying a great popularity among the customers for Manufacturer for Chery Qq Bearing - AC SYSTEM COMPRESSOR for CHERY EASTAR B11 – Qingzhi , The product will supply to all over the world, such as: Latvia , Lebanon , Lahore , Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!