OEM/ODM China Chery Qq6 - Genuine Original forged camshaft for chery car parts – Qingzhi

OEM/ODM China Chery Qq6 - Genuine Original forged camshaft for chery car parts – Qingzhi Detail:

| Product grouping | Engine parts |

| Product name | Camshaft |

| Country of origin | China |

| OE number | 481F-1006010 |

| Package | Chery packaging, neutral packaging or your own packaging |

| Warranty | 1 year |

| MOQ | 10 sets |

| Application | Chery car parts |

| Sample order | support |

| port | Any Chinese port,wuhu or shanghai is best |

| Supply Capacity | 30000sets/months |

The camshaft adjuster is a cam deflection control valve, which is a corner stroke valve, which is composed of a corner stroke electric actuator and an eccentric hemispherical valve. The actuator adopts an integrated structure, and the electric actuator has a built-in servo system.

Principle: Change the opening time of the intake and exhaust valves according to the working needs of the engine. When the engine is under high load, the camshaft adjuster is used to optimize the valve overlap angle according to the engine speed, so as to supply as much fresh air to the combustion chamber as possible, so as to achieve high power and overlap angle, so as to supply the combustion chamber as much as possible Fresh air to achieve high power and torque.

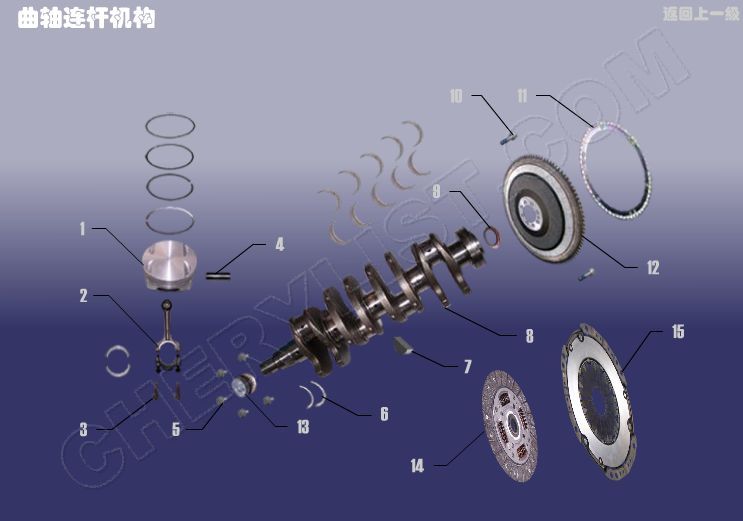

The camshaft is a component of a piston engine. Its function is to control the opening and closing of valves. Although the speed of the camshaft in the four stroke engine is half of that of the crankshaft (the speed of the camshaft in the two-stroke engine is the same as that of the crankshaft), usually its speed is still very high and needs to bear a large torque. Therefore, the design has high requirements for the strength and support surface of the camshaft, and its material is generally high-quality alloy steel or alloy steel. Because the law of valve motion is related to the power and operating characteristics of an engine, camshaft design plays a very important role in the process of engine design.

The main body of the camshaft is a cylindrical rod with approximately the same length as the cylinder bank. Several cams are sleeved on it to drive the valve. The camshaft is supported in the camshaft bearing hole through the camshaft journal, so the number of camshaft journals is an important factor affecting the camshaft support stiffness. If the camshaft stiffness is insufficient, bending deformation will occur during operation, affecting the valve timing.

The side of the cam is egg shaped. It is designed to ensure sufficient intake and exhaust of the cylinder. In addition, considering the durability and running smoothness of the engine, the valve can not have too much impact due to the acceleration and deceleration process in the opening and closing action, otherwise it will cause serious wear of the valve, increased noise or other serious consequences. Therefore, the cam is directly related to the power, torque output and running smoothness of the engine.

Common faults of camshaft include abnormal wear, abnormal sound and fracture. Abnormal wear often occurs before abnormal sound and fracture.

(1) The camshaft is almost at the end of the engine lubrication system, so the lubrication condition is not optimistic. If the oil supply pressure of the oil pump is insufficient due to long service time, or the lubricating oil cannot reach the camshaft due to the blockage of the lubricating oil passage, or the lubricating oil cannot enter the camshaft clearance due to the excessive tightening torque of the fastening bolts of the bearing cover, the camshaft will be abnormally worn.

(2) The abnormal wear of camshaft will increase the gap between camshaft and bearing seat, and the camshaft will move axially, resulting in abnormal sound. Abnormal wear will also increase the gap between the driving cam and the hydraulic tappet, and the cam will collide with the hydraulic tappet, resulting in abnormal noise.

(3) Serious faults such as camshaft fracture sometimes occur. The common causes are hydraulic tappet fragmentation or serious wear, serious poor lubrication, poor camshaft quality and camshaft timing gear fracture.

(4) In some cases, the camshaft failure is caused by human factors, especially when the camshaft is not disassembled correctly during engine maintenance. For example, when removing the camshaft bearing cover, knock it with a hammer or pry it with a screwdriver, or install the bearing cover in the wrong position, resulting in the mismatch between the bearing cover and the bearing seat, or the tightening torque of the fastening bolts of the bearing cover is too large. When installing the bearing cover, pay attention to the direction arrow, position number and other marks on the surface of the bearing cover, and tighten the fastening bolts of the bearing cover with a torque wrench in strict accordance with the specified torque.

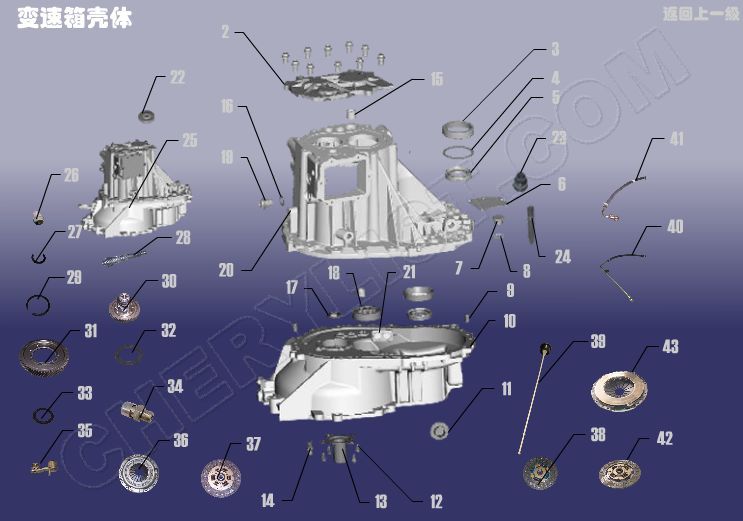

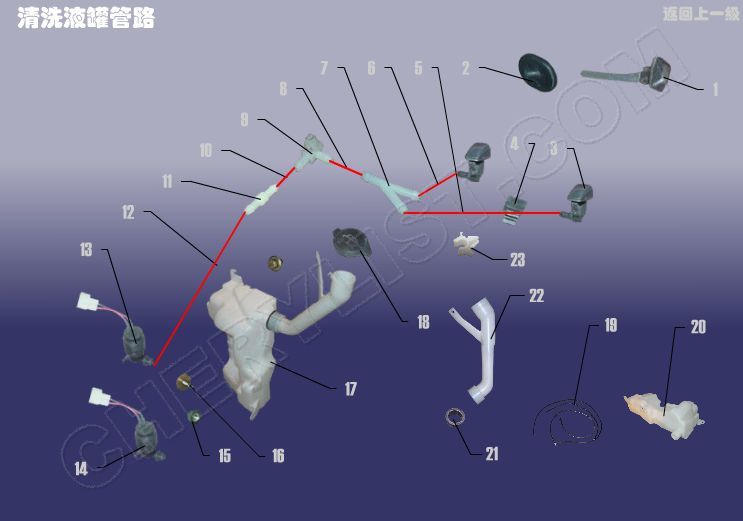

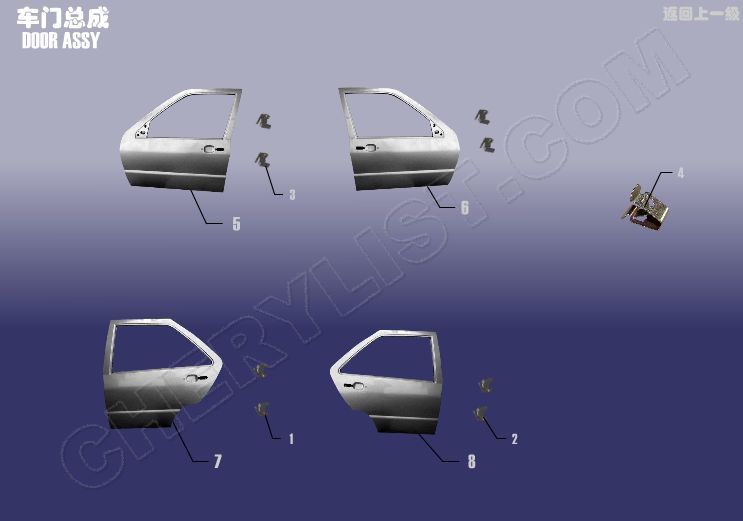

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for OEM/ODM China Chery Qq6 - Genuine Original forged camshaft for chery car parts – Qingzhi , The product will supply to all over the world, such as: Austria , Monaco , Israel , With more than 9 years of experience and a professional team, we have exported our products to many countries and regions all over the world. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.