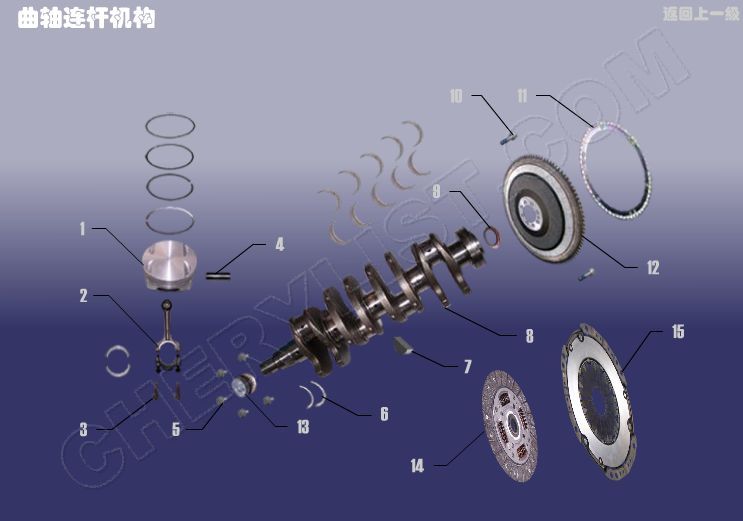

OEM/ODM Manufacturer Chery Jaggi Cylinder Head - ENGINE CRANKSHAFT and CONNECTING ROD MECHANISM for CHERY QQ6 S21 – Qingzhi

OEM/ODM Manufacturer Chery Jaggi Cylinder Head - ENGINE CRANKSHAFT and CONNECTING ROD MECHANISM for CHERY QQ6 S21 – Qingzhi Detail:

473H-1004015 PISTON

2 473H-1004110 CONNECTING ROD ASSY

3 481H-1004115 BOLT-CONNECTING ROD

4 473H-1004031 PISTON PIN

5 481H-1005083 BOLT-HEXAGON FLANGE M8x1x16

6 481H-1005015 THRUSTER-CRANKSHAFT

7 Q5500516 SEMICIRCULAR KEY

8 473H-1005011 CRANKSHAFT ASSY

9 473H-1005030 OIL SEAL RR-CRANKSHAFT 75x95x10

10 473H-1005121 BOLT-FLYWHEEL-M8x1x25

11 473H-1005114 SIGNAL WHEEL-SENSOR CRANKSHAFT

12 473H-1005110 FLYWHEEL ASSY

13 481H-1005051 TIMING GEAR

14 S21-1601030 DRIVEN DISK ASSY

15 S21-1601020 PRESS DISK – CLUTCH

Crank train is the main moving mechanism of engine. Its function is to convert the reciprocating motion of the piston into the rotating motion of the crankshaft, and at the same time, convert the force acting on the piston into the external output torque of the crankshaft to drive the car wheels to rotate. The crank connecting rod mechanism is composed of piston group, connecting rod group, crankshaft, flywheel group and other parts

The function of the crank connecting rod mechanism is to provide a combustion place, convert the expansion pressure of the gas generated after fuel combustion on the piston crown into the rotating torque of the crankshaft and continuously output power.

(1) Change the pressure of the gas into the torque of the crankshaft

(2) Change the reciprocating motion of the piston into the rotary motion of the crankshaft

(3) The combustion force acting on the piston crown is transformed into the torque of the crankshaft to output mechanical energy to the working machinery

1. The fillets at both ends of the crankshaft journal are too small. When grinding the crankshaft, the grinder fails to correctly control the axial stiffness fillets of the crankshaft. In addition to the rough arc surface processing, the fillet radius is also too small. Therefore, during the operation of the crankshaft, there is a large stress concentration at the fillet and shortens the fatigue life of the crankshaft.

2. Crankshaft main journal axis offset (automobile maintenance technology network) https://www.qcwxjs.com/ )The axis deviation of the crankshaft main journal destroys the dynamic balance of the crankshaft assembly. When the diesel engine runs at high speed, it will produce a strong inertial force, resulting in the fracture of the crankshaft.

3. The cold competition of crankshaft is too large. After long-term use, especially after tile burning or cylinder tamping accidents, the crankshaft will have large bending, which should be removed for cold pressing correction. Due to the plastic deformation of the metal inside the crankshaft during correction, great additional stress will be generated, so as to reduce the strength of the crankshaft. If the cold contest is too large, the crankshaft may be damaged or cracked

4. The flywheel is loose. If the flywheel bolt is loose, the crankshaft assembly will lose its original dynamic balance. After the diesel engine runs, it will shake and produce a large inertial force, resulting in crankshaft fatigue and easy fracture at the tail end.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of OEM/ODM Manufacturer Chery Jaggi Cylinder Head - ENGINE CRANKSHAFT and CONNECTING ROD MECHANISM for CHERY QQ6 S21 – Qingzhi , The product will supply to all over the world, such as: Romania , Provence , Accra , In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.