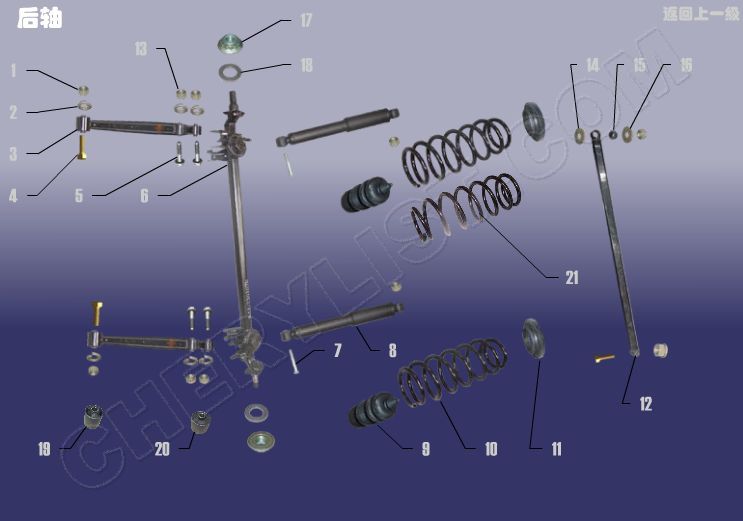

Quality Inspection for Chery Tie Rod - CHASSIS REAR AXLE for CHERY QQ SWEET S11 1.1L – Qingzhi

Quality Inspection for Chery Tie Rod - CHASSIS REAR AXLE for CHERY QQ SWEET S11 1.1L – Qingzhi Detail:

1 Q361B12 NUT

2 Q40312 ELASTIC WASHER

3 S11-3301010 ARM,DRAG-R.

4 Q151B1290 BOLT

5 Q151B1285 BOLT

6 S11-3301070 REAR AXLE WELDMENT ASSY

7 Q151B1255 BOLT

8 S11-2915010 REAR SHOCK ABSORBER ASSY

9 S11-2911033 REAR BUFFER BLOCKAGE

10 S11-2912011 REAR SPIRAL SPRING

11 S11-2911031 REAR SPRING UPPER SOFT COVER

12 S11-3301120 REAR AXLE CROSS SUPPORT ROD ASSY

13 S11-3301201 NUT

14 S11-3301131 WASHER

15 S11-3301133 SLEEVE,RUBBER

16 S11-3301135 WASHER

17 A11-3301017BB LOCK NUT

18 A11-2203207 WASHER

19 S11-3301050 SLEEVE(FRT)

20 S11-3301060 SLEEVE(R.)

21 S11-2912011TA REAR SPRING

Automobile rear axle, namely rear axle: it is divided into drive axle and support axle. The supporting bridge is a supporting bridge that plays a bearing role on the vehicle frame and is mainly affected by the gravity of the vehicle. The drive axle turns the power transmitted from the universal transmission device through 90 °, changes the transmission direction of the force, reduces the speed by the main reducer, increases the torque, and distributes it to the left and right half shafts and drive wheels through the differential.

The drive axle is mainly composed of main reducer, differential, axle shaft and drive axle housing.

main reducer

The main reducer is generally used to change the transmission direction, reduce the speed and increase the torque to ensure that the vehicle has sufficient driving force and appropriate speed. There are many types of main reducers, including single-stage, double-stage, double speed, wheel reducer, etc.

1) A single-stage main reducer is a device that decelerates by a pair of reduction gears, which is called a single-stage reducer. It has simple structure and light weight. It is widely used in light and medium-sized trucks such as Dongfeng bql090.

2) For some heavy-duty trucks with large load, the double-stage main reducer requires a large reduction ratio. If the single-stage main reducer is used for transmission, the diameter of the driven gear must be increased, which will affect the ground clearance of the drive axle, so double reduction is adopted. It is usually called two-stage reducer. The two-stage reducer has two sets of reduction gears to realize twice reduction and torque increase.

In order to improve the meshing stability and strength of bevel gear pair, the first reduction gear pair is spiral bevel gear. The secondary gear pair is a helical cylindrical gear.

The driving bevel gear rotates and drives the driven bevel gear to rotate, so as to complete the first-class deceleration. The driving cylindrical gear of the second stage reduction rotates coaxially with the driven bevel gear, and drives the driven cylindrical gear to rotate for the second stage reduction. Because the driven cylindrical gear is installed on the differential housing, when the driven cylindrical gear rotates, the wheel is driven to rotate through the differential and half shaft.

differential mechanism

The differential is used to connect the left and right half shafts, which can make the wheels on both sides rotate at different angular speeds and transmit torque at the same time. Ensure the normal rolling of wheels. Some multi axle drive vehicles are also equipped with differential in the transfer case or between the through transmission shafts, which is called inter axle differential. Its function is to make the difference between the front and rear driving wheels when the car turns or runs on an uneven road. Domestic cars and other types of cars basically adopt symmetrical bevel gear ordinary differential. Symmetrical bevel gear differential is composed of planetary gear, half shaft gear, planetary gear shaft (cross shaft or a direct pin shaft) and differential housing.

Most cars adopt planetary gear differential. Ordinary bevel gear differential is composed of two or four conical planetary gears, planetary gear shaft, two conical half shaft gears and left and right differential shells.

Half axis

The axle shaft is a solid shaft that transmits the torque from the differential to the wheels, drives the wheels to rotate and drives the car. Due to the different installation structure of the hub, the stress of the half shaft is also different. Therefore, the semi axle is divided into three types: full floating, semi floating and 3 / 4 floating.

Fully floating axle shaft

Generally, large and medium-sized vehicles adopt full floating structure. The inner end of the half shaft is connected with the half shaft gear of the differential by splines, and the outer end of the half shaft is forged with a flange and connected with the hub by bolts. The hub is supported on the half shaft sleeve through two tapered roller bearings far away. The axle shaft sleeve is press fitted with the rear axle housing to form a drive axle housing. With this support form, the axle shaft is not directly connected with the axle housing, so that the axle shaft only bears the driving torque without any bending moment. This kind of axle shaft is called “fully floating” axle shaft. The so-called “floating” means that the half shaft is not subjected to bending load.

The outer end of the fully floating half shaft is a flange, and the disc is integrated with the shaft. However, there are also some trucks that make the flange into separate parts and use flower keys to fit it on the outer end of the half shaft. Therefore, both ends of the half shaft are splines, which can be used interchangeably.

Semi floating axle shaft

The inner end of the semi floating axle shaft is the same as that of the fully floating one, and does not bear bending and torsion. Its outer end is directly supported on the inner side of the half shaft housing through a bearing. This support mode will make the outer end of the half shaft bear bending moment. Therefore, in addition to transmitting torque, this half sleeve also bears bending moment locally, so it is called semi floating half shaft. This type of structure is mainly used for passenger cars. The picture shows the drive axle of Hongqi ca7560 luxury car. The inner end of the half shaft is not subject to bending moment, while the outer end is subject to all bending moment, so it is called semi floating support.

3 / 4 floating axle shaft

3 / 4 floating half shaft is subject to bending moment, which is between half floating and full floating. This type of half axle is not widely used, and it is only used in individual small sleeping cars, such as Warsaw M20 car.

axle housing

Integral axle housing

The integral axle housing is widely used because of its good strength and stiffness, which is convenient for the installation, adjustment and maintenance of the main reducer. Due to different manufacturing methods, the integral axle housing can be divided into integral casting type, middle casting and pressing steel pipe type and steel plate stamping and welding type.

Segmented drive axle housing

The segmented axle housing is generally divided into two sections, which are connected by bolts. The segmented axle housing is easy to cast and process

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Quality Inspection for Chery Tie Rod - CHASSIS REAR AXLE for CHERY QQ SWEET S11 1.1L – Qingzhi , The product will supply to all over the world, such as: Algeria , Egypt , Palestine , "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!