Rapid Delivery for Chery Lamp - WIRE HARNESS ELECTRICITY for chery 1.1L QQ – Qingzhi

Rapid Delivery for Chery Lamp - WIRE HARNESS ELECTRICITY for chery 1.1L QQ – Qingzhi Detail:

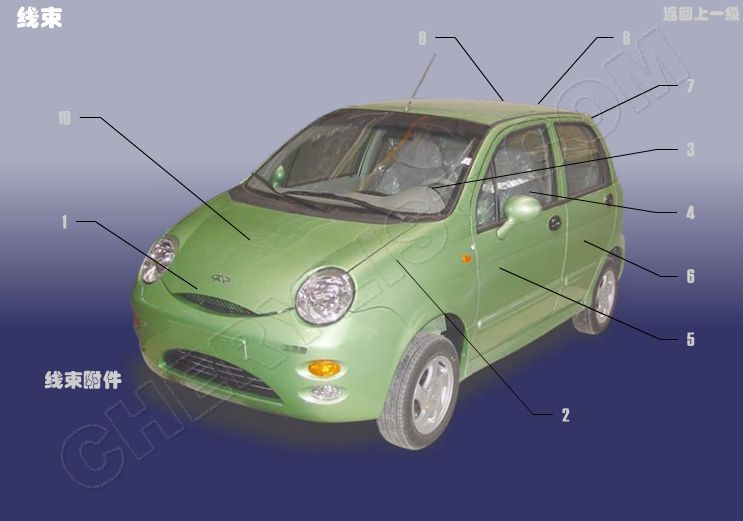

1 S11-3724010BA HARNESS ENGINE ROOM

2 S11-3724013 HARNESS,’MINUS’

3 S11-3724030BB HARNESS INSTRUMENT

4 S11-3724050BB HARNESS INNER

5 S11-3724070 HARNESS DOOR-FRT

6 S11-3724090 HARNESS DOOR-R.

7 S11-3724120 HARNESS,COVER-R.

8 S11-3724140 DEFROSTER ANODE WIRING ASSY

9 S11-3724160 REAR DEFROSTER GROUNDING CONDU

10 S11-3724180BB HARNESS ENGINE

Wire harness

Automobile wire harness is an important component connecting various electrical and electronic equipment of automobile. It transmits electrical signals between power supply, switch, electrical and electronic equipment. It is known as nerve transmission and blood supply. It is the carrier of electrical signal control of automobile. Automobile wire harness is the main body of automobile circuit network. Without wire harness, there will be no automobile circuit. [1]

In order to facilitate installation and maintenance and ensure that the electrical equipment can work under the worst conditions, the wires of different specifications and colors used by the electrical equipment of the whole vehicle are integrated through reasonable arrangement, and the wires are bound into bundles with insulating materials, which is complete and reliable.

choice

The automobile wire harness connects the automobile switch, electrical appliances, sensors, power supply and all electrical and electronic equipment, which are all over the engine compartment, cab and cab of the automobile. Due to the use characteristics of the automobile itself, such as: it must repeatedly experience harsh environments and service conditions such as hot summer, cold winter and turbulence, which determines the technical requirements of Automobile Electrical and electronic equipment. Therefore, the technical requirements of automobile wire harness mainly include: correctness and continuity of circuit, resistance to vibration, impact, alternating damp heat, high temperature, low temperature, salt fog and industrial solvent. [2]

1) Correct selection of wire cross-sectional area

The electrical equipment on the vehicle selects the cross-sectional area of the wire used according to the load current. For electrical equipment that works for a long time, 60% of the actual current carrying capacity of the wire can be selected; 60% – 100% of the actual current carrying capacity of wires can be used for electrical equipment working for a short time.

2) Selection of wire color code

In order to facilitate identification and maintenance, the wires in the wire harness adopt different colors.

For the convenience of marking in the circuit diagram, the colors of wires are represented by letters, and the colors represented are annotated in each circuit diagram.

Failure cause broadcast

Common faults of automobile lines include poor contact of connectors, short circuit between wires, open circuit, grounding, etc.

The causes are as follows:

1) Natural damage

The use of wire harness exceeds the service life, aging the wire, cracking the insulation layer, and significantly reducing the mechanical strength, resulting in short circuit, open circuit, grounding, etc. between the wires, causing the wire harness to burn out. The oxidation and deformation of harness terminals, resulting in poor contact, will cause the electrical equipment to not work normally.

2) Damage to wire harness due to failure of electrical equipment

In case of overload, short circuit, grounding and other faults of electrical equipment, the wire harness may be damaged.

3) Human fault

When assembling or overhauling auto parts, metal objects crush the wire harness and break the insulation layer of the wire harness; Improper position of wire harness; Wrong lead position of electrical equipment; The positive and negative leads of the battery are connected reversely; When repairing circuit faults, random connection and cutting of wire bundles and wires can cause abnormal operation of electrical equipment and even burn out wire bundles. [1]

Detection and judgment broadcasting

1) Detection and judgment of wire harness burn out fault

The wire harness is burnt out suddenly, and the burning speed is very fast. Generally, there is no safety device in the burnt out circuit. The rule of wire harness burning is: in the circuit of the power supply system, the wire harness burns wherever it is grounded, and the junction between the burned and intact parts can be considered as wire grounding; If the wire harness burns out to the wiring part of an electrical equipment, it indicates that the electrical equipment is faulty.

2) Detection and judgment of short circuit, open circuit and poor contact between lines

-The wire harness is squeezed and impacted by the outside, resulting in the damage of the wire insulation layer in the wire harness, resulting in the short circuit between wires, causing some electrical equipment out of control and fuse fusing.

When judging, disconnect the wire harness connectors at both ends of the electrical equipment and the control switch, and use the electricity meter or test lamp to detect the short circuit of the line.

-In addition to the obvious fracture phenomenon, the common faults of wire open circuit mostly occur between wires and wire terminals. After some wires are broken, the outer insulation layer and wire terminal are intact, but the inner core wire and wire terminal of the wire have been broken. During the judgment, the tensile test can be conducted on the conductor wire and conductor terminal suspected of open circuit. During the tensile test, if the conductor insulation layer gradually becomes thinner, it can be confirmed that the conductor is open circuit.

-The circuit is in poor contact, and most of the faults occur in the connector. When the fault occurs, the electrical equipment will not work normally. When judging, turn on the power supply of the electrical equipment, touch or pull the relevant connector of the electrical equipment. When touching a connector, the operation of the electrical equipment is either normal or abnormal, indicating that the connector is faulty.

Replace broadcast

Appearance inspection

1) The model of the new wire harness shall be the same as that of the original model. The connection between the wire terminal and the wire is reliable. You can pull each connector and the wire by hand to see if they are loose or fall off.

2) Compare the new wire harness with the original wire harness, such as the size of wire harness, wire terminal connector, wire color, etc. In case of any doubt, use a multimeter to test and confirm that the wire harness is intact before replacement.

install

The connectors, plugs and sockets of all electrical equipment must correspond to the sockets and plugs on the wire harness. After the connecting wires are connected with the electrical equipment, a certain margin shall be reserved, and the wires shall not be pulled too tightly or placed too loosely.

Line inspection

1) Line inspection

After replacing the wire harness, first check whether the connection between the wire harness connector and the electrical equipment is correct, and whether the positive and negative poles of the battery are connected correctly.

2) Power on test

The grounding wire of the battery can not be connected temporarily. Use a 12V, 20W bulb as the test lamp, connect the test lamp in series between the negative pole of the battery and the grounding end of the frame, and turn off the switches of all electrical equipment on the vehicle. The test lamp should not be on when it is normal, otherwise it indicates that there is a fault in the circuit. When the circuit is normal, remove the bulb, connect a 30A fuse in series between the negative pole of the battery and the grounding end of the frame, do not start the engine, turn on the power supply of each electrical equipment on the vehicle one by one, check the electrical equipment and circuit, and remove the fuse and connect the grounding wire of the battery after confirming that the electrical equipment and circuit are free of fault.

The common specifications of wires in the harness include wires with nominal cross-sectional areas of 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 4.0, 6.0 and other square millimeters. They all have allowable load current values and are used for wires of electrical equipment with different powers. Taking the whole vehicle harness as an example, the 0.5 specification line is applicable to instrument lights, indicator lights, door lights, ceiling lights, etc; 0.75 specification line is applicable to license plate lights, front and rear small lights, brake lights, etc; 1.0 specification line is applicable to turn signal lamp, fog lamp, etc; 1.5 the specification line is applicable to headlights, horns, etc; The main power line, such as generator armature line, grounding wire, etc., requires 2.5 to 4 mm2 wires. This only means that for ordinary cars, the key depends on the maximum current value of the load. For example, the grounding wire and positive power wire of the battery are special car wires used alone. Their wire diameters are relatively large, at least more than ten square millimeters. These “Big Mac” wires will not be incorporated into the main harness.

Before arranging the harness, draw the harness diagram in advance. The harness diagram is different from the circuit schematic diagram. The circuit schematic diagram is an image describing the relationship between various electrical parts. It does not reflect how the electrical parts are connected with each other, and is not affected by the size and shape of various electrical components and the distance between them. The harness diagram must take into account the size and shape of each electrical component and the distance between them, and also reflect how the electrical components are connected to each other.

After the technicians of the wire harness factory made the wire harness wiring board according to the wire harness diagram, the workers cut and arranged the wires according to the provisions of the wiring board. The main harness of the whole vehicle is generally divided into engine (ignition, EFI, power generation, starting), instrument, lighting, air conditioning, auxiliary appliances and other parts, including main harness and branch harness. A whole vehicle main harness has multiple branch harnesses, just like tree poles and tree branches. The main harness of the whole vehicle often takes the instrument panel as the core part and extends forward and backward. Due to the length relationship or convenient assembly, the harness of some vehicles is divided into front harness (including instrument, engine, front light assembly, air conditioner and battery), rear harness (tail lamp assembly, license plate lamp and trunk lamp), roof harness (door, ceiling lamp and audio horn), etc. Each end of the harness will be marked with numbers and letters to indicate the connection object of the wire. The operator can see that the mark can be correctly connected to the corresponding wires and electrical devices, which is particularly useful when repairing or replacing the harness. At the same time, the color of the wire is divided into monochrome wire and two-color wire. The purpose of the color is also specified, which is generally the standard set by the car factory. The Chinese industry standard only stipulates the main color. For example, it stipulates that single black is dedicated to grounding wire and red is used for power wire. It can not be confused.

The harness is wrapped with woven thread or plastic adhesive tape. For safety, processing and maintenance convenience, woven thread wrapping has been eliminated and is now wrapped with adhesive plastic tape. The connection between harness and harness and between harness and electrical parts adopts connector or lug. The connector is made of plastic and is divided into plug and socket. The wire harness is connected with the wire harness with a connector, and the connection between the wire harness and electrical parts is connected with a connector or lug.

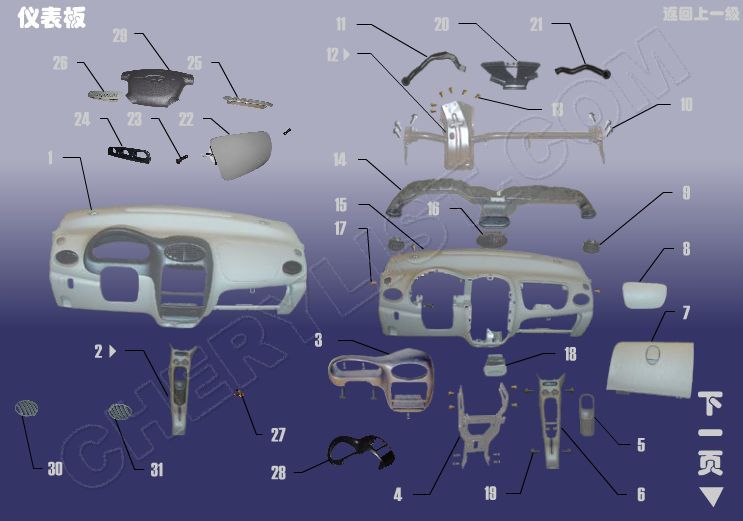

Product detail pictures:

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Rapid Delivery for Chery Lamp - WIRE HARNESS ELECTRICITY for chery 1.1L QQ – Qingzhi , The product will supply to all over the world, such as: Botswana , Swiss , Latvia , You can always find the solutions you have to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We have been looking forward to work with you for a win-win situation.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!