Short Lead Time for Chery Envy Steering Gear - QR523 TRANSMISSION CASING,TRANSMISSION for CHERY TIGGO T11 – Qingzhi

Short Lead Time for Chery Envy Steering Gear - QR523 TRANSMISSION CASING,TRANSMISSION for CHERY TIGGO T11 – Qingzhi Detail:

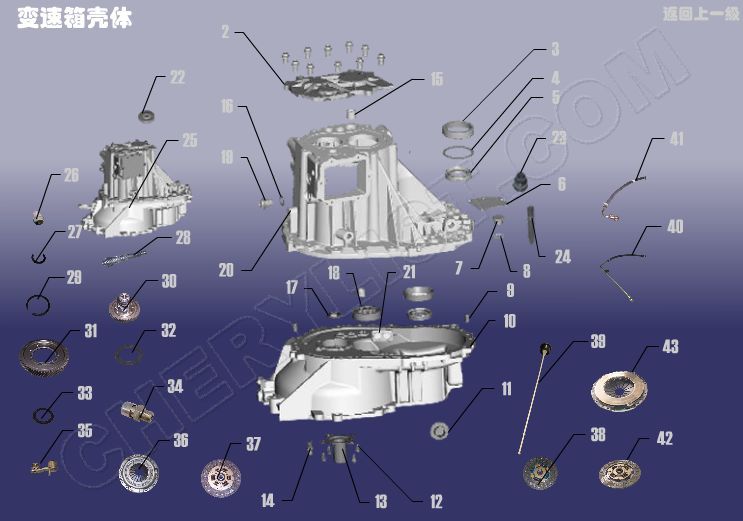

2 QR523-1701301 COVER BEARING

3 QR523-1701703 BEARING FRT and R.

4 QR523-1701704AA GASKET – ADJUST

5 QR523-1701203 SEAL OIL-DIFF.

6 QR523-1701109 BAFFLE,OIL

7 QR523-1701102 PLUG MAGNET

8 QR523-1701103 PLAIN WASHER MAGNET PLUG

9 Q5211020 POSITION PIN

10 QR523-1701201 CASING CLUTCH

11 QR523-3802505 BUSH – ODOMETER

12 Q1840612 BOLT

13 QR523-1701202 SHOES,RELEASE BEARING

14 QR523-1602522 SEAT,BAL-RELEASE FORK

15 QR523-1702331 BEARING SHIFT ASSY

16 QR523-1701105 PLAIN WASHER PLUG

17 QR523-1701206 SEAL OIL-INPUT SHAFT

18 QR523-1701502 BEARING OUTPUT SHAFT-FRT

19 QR523-1701104 PLUG

20 QR523-1701101 CASE TMISSION

21 QR523-1701220 MAGNET SET

22 QR523-1701302 PIPE – GUIDE

23 QR523-1701204 BUSH – SEAL

24 QR523-1701111 STUD

25 QR523-1700010BA TRANSMISSION ASSY – QR523

26 QR518-1701103 DEVICE – SHIFT STEEL BALL POSITION

27 QR523-1701403AB RING – SNAP

28 QR523-1701501BA SHAFT – OUTPUT

29 QR523-1701508AB RING – SNAP

30 QR523-1701700BA DRIVING and DIFF

31 QR523-1701707BA GEAR – MAIN REDUCER DOORIVEN

32 QR523-1701719AB GASKET – ADJUST

33 QR523-1701719AE ADJUSTMENT WASHER

34 QR523-1702410 PLUG – VENT

35 QR523-1702420BA GEAR SHIFT ARM

36 T11-1601020BA COVER ASSY – CLUTCH

37 T11-1601030BA DISK ASSY – CLUTCH DOORIVEN

38 T11-1601030DA DISK ASSY – CLUTCH DOORIVEN

39 T11-1502150 ROD ASSY – OIL LEVER GAUGE

40 T11-1503020 PIPE – INLET

41 T11-1503040 PIPE ASSY – RETURN

42 SMN132443 DISC CLUTCH

43 SMR534354 CASING SET CLUTCH

Transmission housing is a load-bearing part, which is generally made of die-casting aluminum alloy through special die-casting, with irregular and complex shape.

The gearbox shell was mainly made of gray cast iron in the early stage, which has the advantages of easy forming, good shock absorption and low cost. With the improvement of users’ requirements for vehicle driving comfort and the maturity of lightweight technology, the gearbox shell on the car is replaced by aluminum alloy. The gearbox shell is mainly made of gray cast iron and aluminum alloy.

The transmission housing is a housing structure used to install the transmission mechanism and its accessories. In order to reduce the wear and power loss of parts caused by internal friction, lubricating oil must be injected into the shell and the working surfaces of gear pairs, shafts, bearings and other parts must be lubricated by splash lubrication. Therefore, there is an oil filler on one side of the shell, an oil drain plug at the bottom, and the oil level height is controlled by the position of the oil filler.

An oil seal assembly is installed in the rear bearing cover of the transmission. Install sealing gaskets at the joint surfaces of each bearing cover, rear cover, upper cover, front and rear housing, and apply sealant to prevent oil leakage. In order to prevent the leakage of lubricating oil caused by the increase of oil temperature and pressure during the operation of the transmission, a vent plug is installed on the transmission mechanism seat and the rear bearing cover of the transmission.

The main function of the gearbox shell is to support the transmission shafts, ensure the center distance and parallelism between the shafts, and ensure the correct installation of the gearbox shell parts and other connected parts. The processing quality of the gearbox shell directly affects the assembly accuracy and operation accuracy of the transmission assembly, as well as the working accuracy and service life of the vehicle, Therefore, the quality requirements are high.

Processing difficulties of gearbox housing:

1. There are many processing contents, and the machine tools and cutting tools need to be changed frequently.

2. The requirement of machining accuracy is high. It is difficult to guarantee the machining quality by using ordinary machine tools, and the process flow is long, the turnover times are many, and the production efficiency is difficult to improve.

3. The shape is complex, and most of them are thin-walled shells, with poor workpiece stiffness, which is difficult to clamp.

Product detail pictures:

Related Product Guide:

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for Short Lead Time for Chery Envy Steering Gear - QR523 TRANSMISSION CASING,TRANSMISSION for CHERY TIGGO T11 – Qingzhi , The product will supply to all over the world, such as: Latvia , Nepal , Egypt , Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.