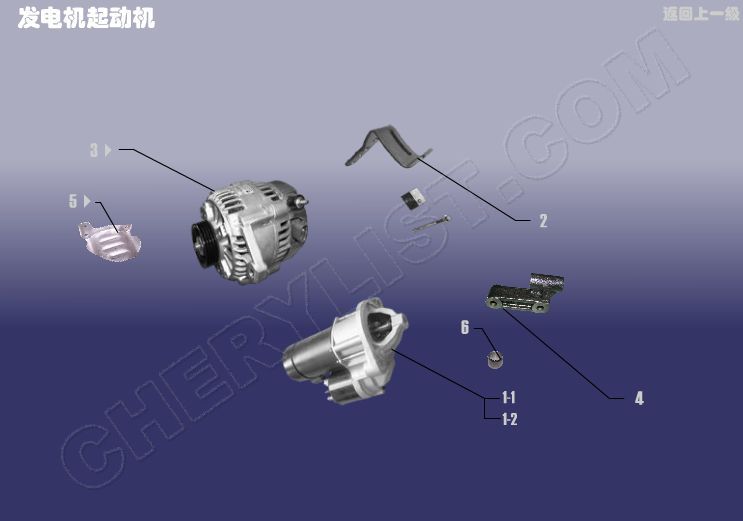

ENGINE STARTER for CHERY A1 KIMO S12

1-1 S12-3708110BA STARTER ASSY

1-2 S12-3708110 STARTER ASSY

2 S12-3701210 ADJUST BRACKET-GENERATOR

3 FDJQDJ-FDJ GENERATOR ASSY

4 S12-3701118 BRACKET-GENERATOR LWR

5 FDJQDJ-GRZ HEAT INSULATOR COVER-GENERATOR

6 S12-3708111BA STEEL SLEEVE

According to the working principle, starters are divided into DC starters, gasoline starters, compressed air starters, etc. Most internal combustion engines use DC starters, which are characterized by compact structure, simple operation and easy maintenance. Gasoline starter is a small gasoline engine with clutch and speed change mechanism. It has high power and is less affected by temperature. It can start large internal combustion engine and is suitable for high and cold areas. Compressed air starters are divided into two types: one is to inject compressed air into the cylinder according to the working sequence, and the other is to drive the flywheel with a pneumatic motor. The purpose of compressed air starter is similar to gasoline starter, which is usually used for the starting of large internal combustion engine.

DC starter is composed of DC series motor, control mechanism and clutch mechanism. It specially starts the engine and needs strong torque, so it has to pass a large amount of current, up to hundreds of amperes.

The torque of DC motor is large at low speed and gradually decreases at high speed. It is very suitable for starter.

The starter adopts DC series motor, and the rotor and stator are wound with thick rectangular section copper wire; The driving mechanism adopts reduction gear structure; The operating mechanism adopts electromagnetic magnetic suction

As we all know, the starting of the engine needs the support of external forces, and the automobile starter is playing this role. Generally speaking, the starter uses three parts to realize the whole startup process. The DC series motor introduces the current from the battery and makes the driving gear of the starter produce mechanical motion; The transmission mechanism engages the driving gear into the flywheel ring gear and can automatically disengage after the engine is started; The on-off of the starter circuit is controlled by an electromagnetic switch. Among them, the motor is the main component inside the starter. Its working principle is the energy conversion process based on Ampere’s law that we contact in junior middle school physics, that is, the force of the energized conductor in the magnetic field. The motor includes necessary armature, commutator, magnetic pole, brush, bearing, housing and other components. Before the engine runs with its own power, it must rotate with the help of external force. The process that the engine transits from static state to self running with the help of external force is called engine starting. There are three common starting modes of engine: manual starting, auxiliary gasoline engine starting and electric starting. Manual starting adopts the way of rope pulling or hand shaking, which is simple but inconvenient, and has high labor intensity. It is only suitable for some low-power engines, and it is only reserved as a backup way on some cars; Auxiliary gasoline engine starting is mainly used in high-power diesel engine; The electric starting mode has the advantages of simple operation, rapid starting, repeated starting ability and remote control, so it is widely used in modern vehicles.