I-QR523 Ukuhanjiswa kokuhambisa, ukudluliswa kwe-Chery Tiggo T11

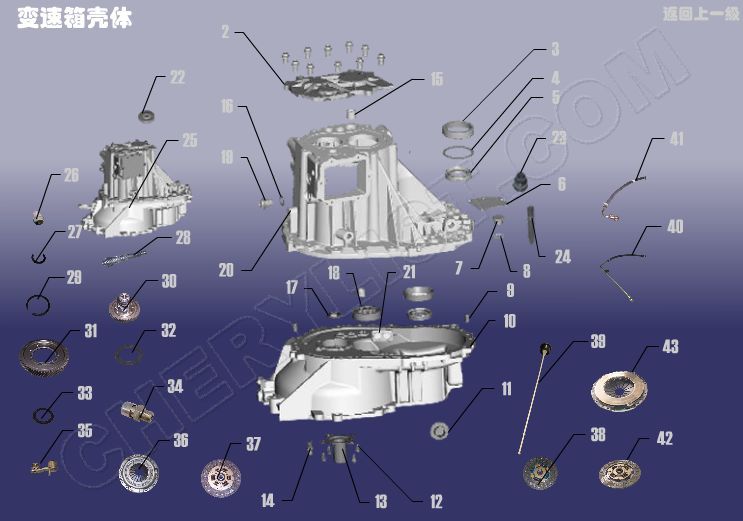

2 QR523-1701301 Isembozo

3 QR523-1701703 Ukuthwala FRT no-R.

4 QR523-1701704AA Gasket - Swap

I-5 QR523-1701203 seal kawoyela.

I-6 QR523-1701109 iyaxaka, uwoyela

7 QR523-171102 Plug Magnet

I-7 QR523-1701103 I-Plain Washer Magnet plug

9 Q5211020 isikhundla se-PIN

10 QR523-1701201 Clutch Clutch

11 QR523-3802505 Bush - Odometer

12 Q1840612 Bolt

13 QR523-1701202 izicathulo, ukukhishwa kwenhliziyo

14 QR523-1602522 Isihlalo, Imfoloko Bal-Resed Fork

I-15 QR523-1702331 Ukuthwala Shift Assesy

I-Plug engu-16 QR523-1701105

I-17 QR523-1701206 SAHF SHAFT

I-18 QR523-1701502 Ukubeka Umkhawulo Whaft-frt

19 QR523-1701104 Ipulaki

I-20 QR523-1701101 IQINISO

21 QR523-1701220 Magnet Set

22 QR523-1701302 Pipe - Umhlahlandlela

23 QR523-1701204 Bush - Seal

24 QR523-1701111 Stud

25 QR523-1700010BA Transfer Assess - QR523

26 QR518-1701103 Idivaysi - Isikhundla sebhola lensimbi

27 QR523-1701403AB RIng - Snap

I-28 QR523-1701501BA SHAFT - Okukhipha

29 QR523-1701508B Ring - Snap

30 QR523-1701700BA ukushayela futhi kuyahlukana

I-31 QR523-1701707BA GEAR - ISIQINISEKISO SAMAHHALA SOKUGCINA

32 QR523-1701719BAB GASCKET - Dlulisa

33 QR523-1701719AE Ukulungiswa kwe-Washer

34 QR523-1702410 plug - Vent

35 QR523-1702420BA Gear Shift ARM

36 T11-1601020BA Cover Assess - Clutch

37 T11-160103ba Disk Assess - Clutch Activenven

38 t11-160103da disk assy - Clutch activenven

I-39 T11-1502150 I-ROD ASSY - I-OIL LEVER Gauge

40 T11-1503020 Pipe - Inlet

I-41 T11-1503040 Pipe Aszy - Buyisela

I-42 SMN132443 Disc Clutch

I-43 SMR534354 Clutch Set Clutch

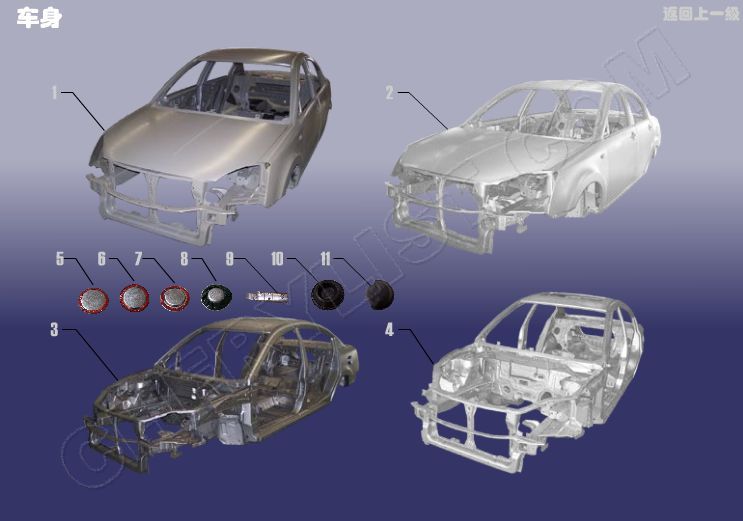

Ukudluliselwa Kwezindlu kuyingxenye ethwala umthwalo, okuvame ukwenziwa nge-aluminium alloy yokufa ngokukhonkotha okukhethekile, ngesimo esingajwayelekile nesinzima.

I-gearbox Shell yenziwa ikakhulukazi ngensimbi empunga i-iron esekuqaleni, enobuhle bokuthola okulula, ukumunyanisa okuhle nokushaqeka nezindleko eziphansi. Ngokuthuthukiswa kwezidingo zabasebenzisi zokushayela imoto yokushayela imoto kanye nokuvuthwa kobuchwepheshe obungasindi, igobolondo le-gearbox emotweni lithathelwa indawo yi-aluminium alloy. I-Gearbox Shell yenziwa ikakhulukazi ngensimbi empunga yensimbi ne-aluminium alloy.

Indlu yokuhambisa yisakhiwo sezindlu esisetshenziselwa ukufaka indlela yokuhambisa kanye nezinto zayo. Ukuze unciphise ukugqoka kanye nokulahleka kwamandla kwezingxenye ezibangelwa ukungqubuzana kwangaphakathi, uwoyela wokugcobiwa kufanele kufakwe egobolondweni kanye nezindawo ezisebenzayo zamabhande ngababili, imigodi, amabele nezinye izingxenye kufanele zithathwe ngokugcotshwa kokugcoba. Ngakho-ke, kukhona i-filler kawoyela ngakolunye uhlangothi lwegobolondo, ipulaki lokukhipha uwoyela ezansi, futhi ukuphakama kwamafutha kulawulwa yisikhundla se-fayela.

Kufakwe umhlangano we-kawoyela wesembozo sokuhambisa emuva kokudluliselwa. Faka ama-caskets ahlanganisiwe endaweni ehlanganisiwe yesembozo ngasinye esithwala, ikhava engemuva, ikhava ephezulu, ngaphambili nangemuva nangezindlu zangemuva, bese usebenzisa i-sealant ukuvikela ukuvuza kwamafutha. Ukuze uvikele ukuvuza kwamafutha okugcoba okubangelwa ukwanda kwamazinga okushisa kawoyela kanye nengcindezi ngesikhathi sokusebenza kokuhambisa, ipulaki le-vent lifakiwe esihlalweni sokudluliselwa kwemali kanye nesembozo esingemuva sokuhambisa.

Umsebenzi oyinhloko we-Gearbox Shell ukusekela imishanguzo yokuhambisa, uqinisekise ibanga eliphakathi nendawo kanye nokufana phakathi kwemithi, futhi uqinisekise ukufakwa okulungile kwezingxenye zamagobolondo egiya nezinye izingxenye ezixhunyiwe. Ikhwalithi yokusebenza ye-gearbox Shell ithinta ngqo ukunemba komhlangano kanye nokunemba komhlangano wokudlulisela, kanye nokunemba okusebenzayo kanye nempilo yemoto yemoto, ngakho-ke, izidingo zekhwalithi ziphezulu.

Ukucubungula ubunzima bezindlu zeGearbox:

1. Kunokuqukethwe okuningi okusebenzayo, futhi amathuluzi omshini namathuluzi okusika adinga ukushintshwa kaningi.

2. Isidingo sokunemba kwemishini siphezulu. Kunzima ukuqinisekisa ikhwalithi yemishini ngokusebenzisa amathuluzi omshini ajwayelekile, futhi ukugeleza kwenqubo isikhathi eside, izikhathi eziningi zokushintshana zinzima ukuthuthuka.

3